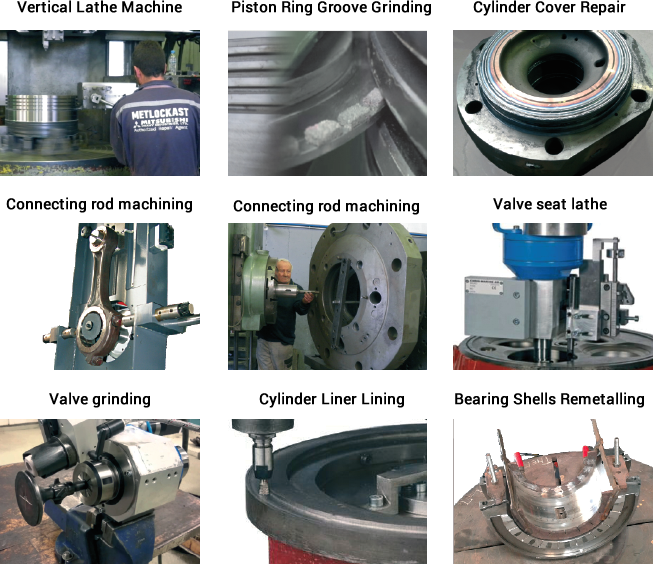

Radials, Borings, Lathes, Milling, Grinding, High Pressure rolling

Highest qualified maintenance work

- Vertical Lathe

- Boring vertical / horizontal

- Radial

- Milling

- Hydraulic bending press

- Annealing ovens

- Grinders

- Spindle High pressure Rolling

In-situ Metalock repairs

Repairing broken, cranked or otherwise damaged cast parts always represents a great challenge as cast iron can only be welded to a limited extent.

Metlockast uses a special Metalock procedure as a variable alternative to welding that today is the preferred method in industry and marine shipping. This procedure enables Metalock to specialize in the cold repair of damaged industrial components made from cast iron, steel and aluminium.

The Metalock procedure offers many advantages and:

- is a cold process that eliminates thermal stress and resultant component distortion

- is an on-site repair that dispenses with the need for disassembly and off-site transport

- minimizes the downtime of valuable equipment

- is recognized by classification societies and eliminates the need to purchase new, expensive cast-iron parts